Lu'an Zhixiang Electronic Technology Co., Ltd. mainly has four major businesses: automotive electronics, SMT surface mount, intelligent driving school training, and intelligent cockpit. The automotive electronics business includes component research and development, new car sample design, automotive testing, and component inspection; SMT SMT SMT bu

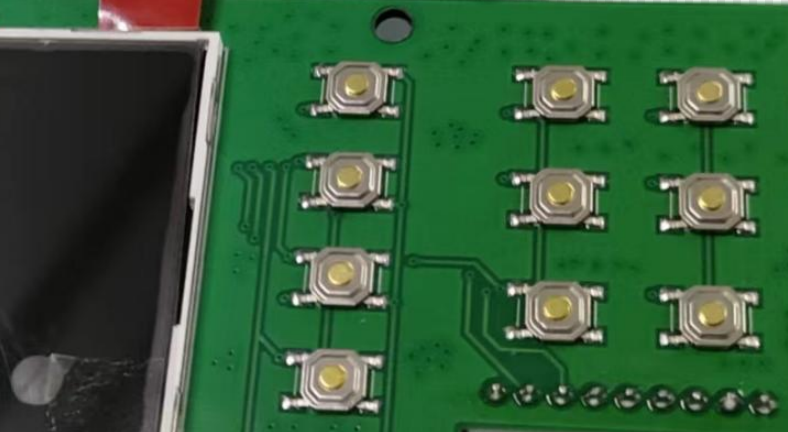

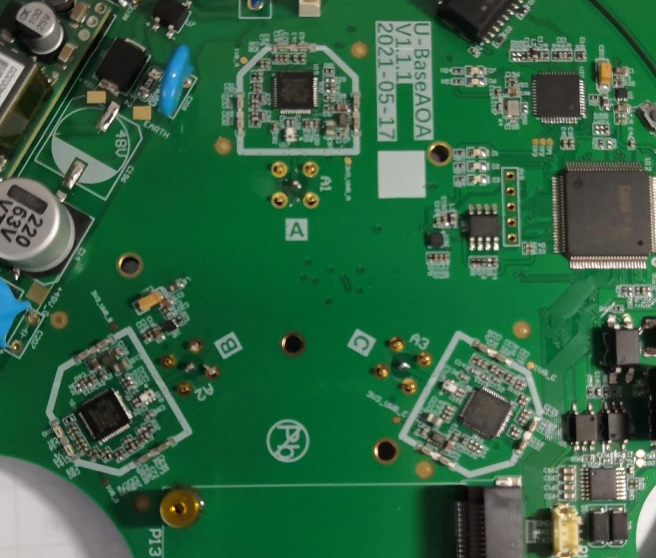

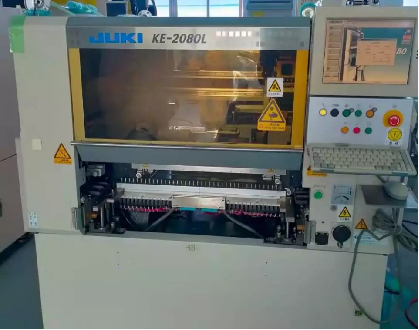

Lu'an Zhixiang Electronic Technology Co., Ltd. mainly has four major businesses: automotive electronics, SMT surface mount, intelligent driving school training, and intelligent cockpit. The automotive electronics business includes component research and development, new car sample design, automotive testing, and component inspection; SMT SMT SMT business provides one-stop services for circuit board soldering and assembly, undertaking SMT small, large, and large batch order soldering, as well as research and development sample soldering, circuit board component allocation, component agency distribution, and PCB production; The intelligent driving school training business provides intelligent teaching through the intelligent driving training system and has a driving school intelligent management system platform; The intelligent cockpit business provides the supply of intelligent cockpit system components for commercial vehicles and RVs.

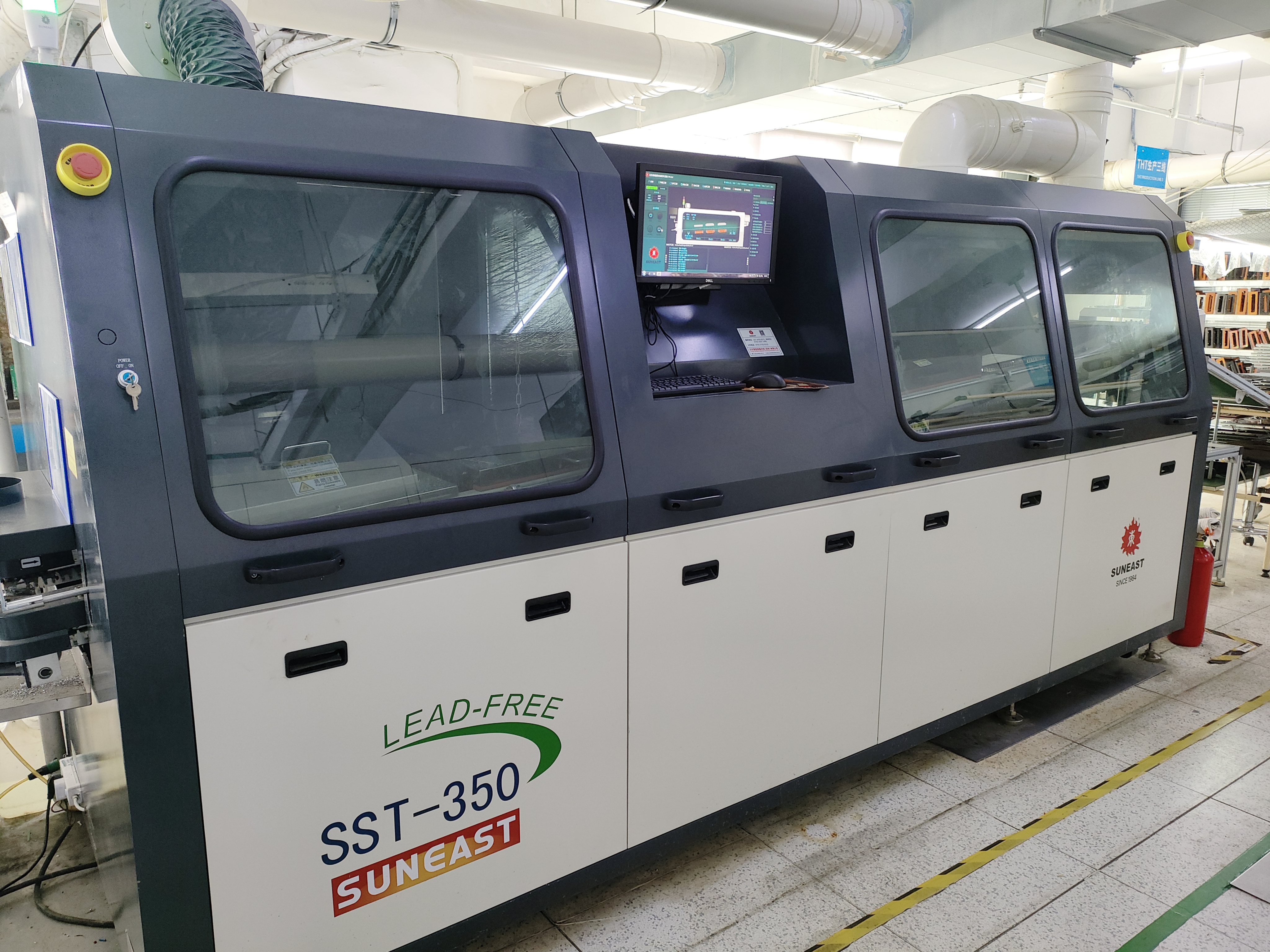

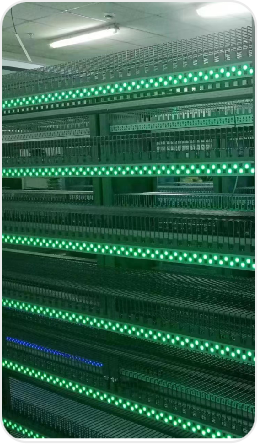

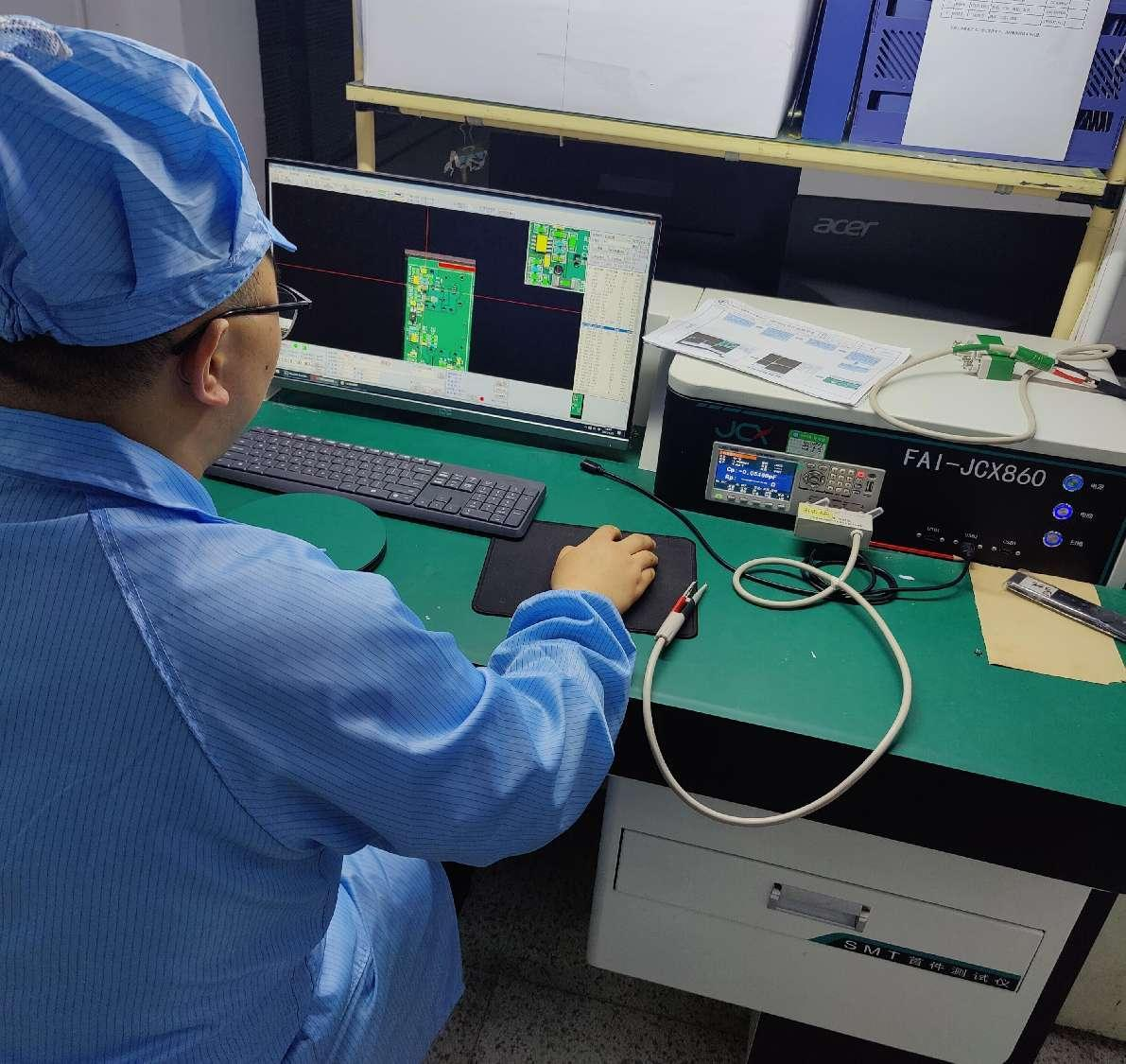

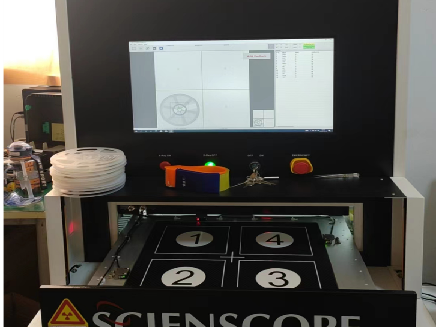

The company adopts intelligent warehouse lighting guidance management, and implements quality control measures such as full process scanning and tracking through part numbers and unique codes. The main processing equipment includes 5 lines of JUKI series medium speed machines, 2 lines of Yamaha series high-speed machines, 3 lines of Jintuo wave soldering, 1 line of Zhishengwei selective wave soldering, 2 assembly and testing lines, 2 blue eye first piece machines and 4 sets of Shenzhou AOI testing equipment, 1 set of Dezhi ICT equipment, 1 set of high and low temperature aging cabinet, 1 set of vibration testing machine, 1 set of BGA repair table, 2 sets of Shuaike fully automatic tool changing and precision carving machines, supporting wave soldering carriers, testing fixture processing workshop, three proof coating workshop, etc. The processed products involve various electronic products such as industrial control boards and network communication, medical products, military, automotive electronics, satellite communication, etc.

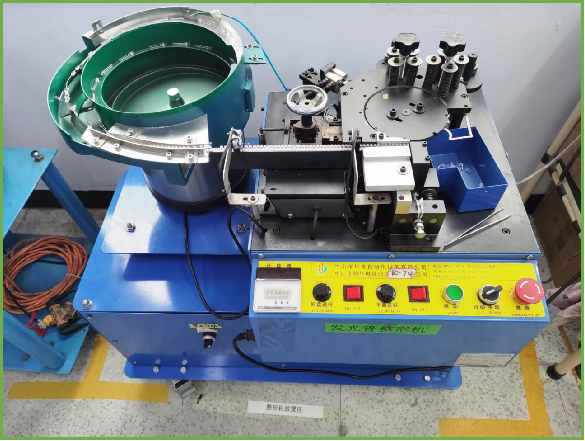

DIP plug-in processing is a part of the PCBA electronic processing process, with relatively more manual operations and higher requirements for management. We have achieved high consistency and reliability in our DIP processing services by implementing a comprehensive quality management system (ISO9001:2015) and equipping ourselves with constantly improving automation equipment, fixtures, etc., earning praise from our customers. At present, there are 2 THT plug-in wave soldering production lines, 2 tin dipping production lines, 3 manual soldering production lines, and 4 assembly lines.